Select or drop a image or 3D model here to search.

We support JPG, JPEG, PNG, GIF, WEBP, GLB, OBJ, STL, FBX. More formats will be added in the future.

Asset Overview

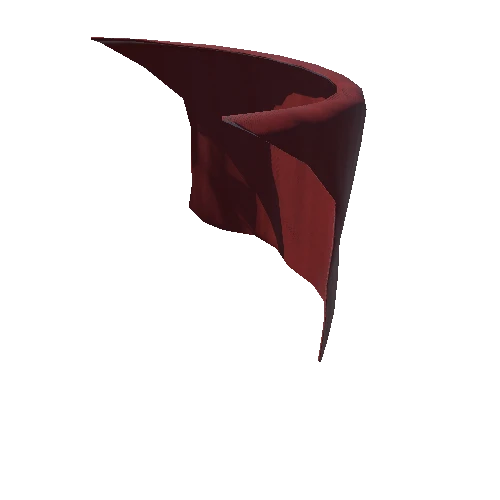

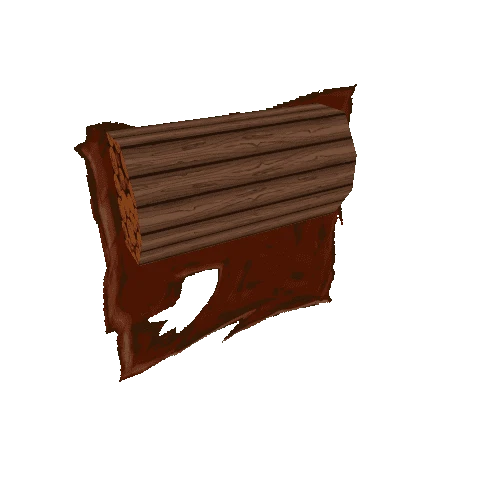

Final fit-up flange to slip over deformed dryer vent pipe to a geometric shape for eventual connection to a fume extraction system. Thin-walled 4" vent pipe was sealed in place with expanding foam and tiled out to prevent ice buildup in -30C weather, Tee expanding foam casued the pipe to deform as it was pressing against a wall stud and the resulting shape was no longer circular or even elliptical. A 3d scan was conducted, scaled to size and a cross-section developed where the fitting would be located. A test fitting (no flange for vent pipe or insulated closure) was developed and printed and fit to the original pipe. The shape is accurate however the seam in the pipe was not detected by the 3D scan so must be added later.

Recommended for you